Services & custom development

Lambda-X offers a full program of service and customization for its instruments and software applications.

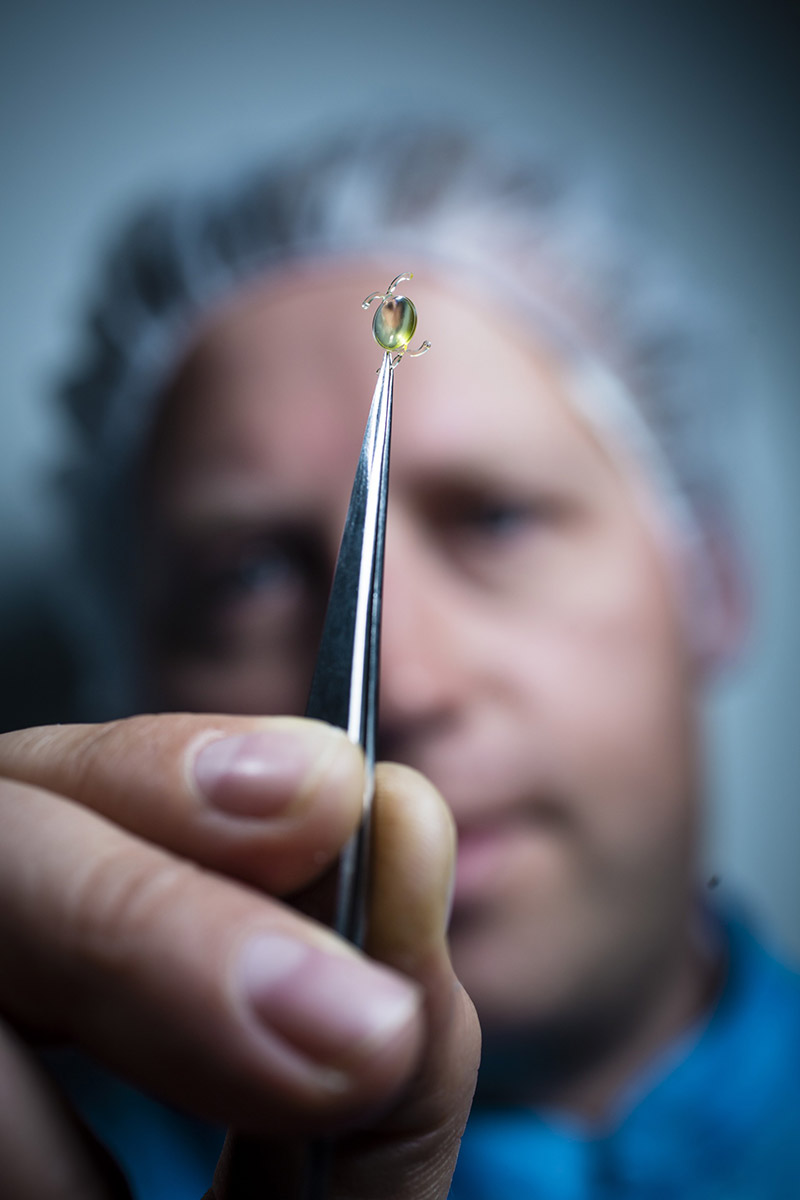

Custom development

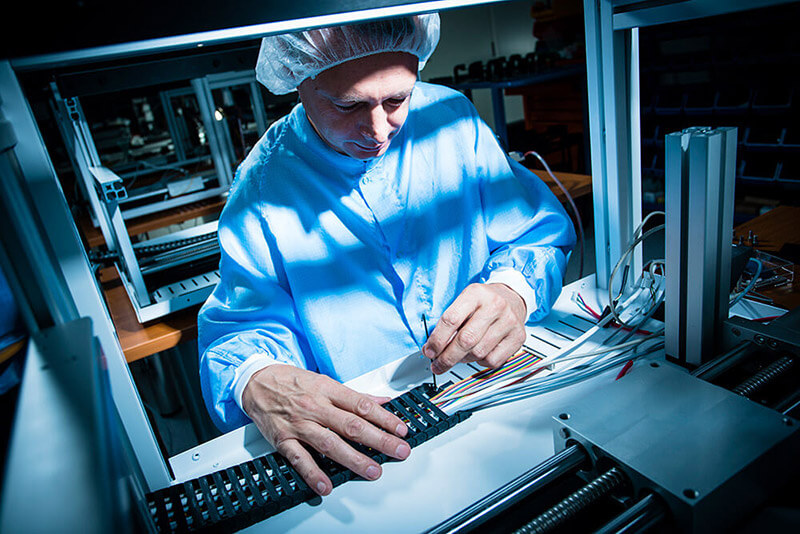

Thanks to its long expertise in project development in space an industry, Lambda-X offers a full program of custom development, for both hardware and software. The development can cover, but are not limited to:

- Development of new software functionalities.

- Development of dedicated “production modes” in order to adapt the instrument to your specific workflow.

- Development of customized hardware interface.

- Development of innovative solutions combining our standard instruments with another technology in order to optimize your workflow and improve your production throughput.

- Development of a completely specific solution “from scratch” in order to address your most stringent needs.

Technical Support Agreement (TSA)

Each Lambda-X instrument is delivered with one year of technical support. Our technical support team can:

- Help you find your way in the setting of the different software parameters.

- Access your instruments remotely to assess any issue or question you may have.

- Analyze your results on the base of measurement projects and configuration files you can send us any time.

- Make a first remote diagnostic in case of hardware issue.

On-site recertification of your instrument

On-site training

A committed team of experts is available for onsite training. When purchasing a high-end metrology instrument it is important to get the best of it immediately after its installation. To this end, a thorough onsite training of your metrology and production engineering team members is of paramount importance in order for them to deeply understand the numerous advanced capabilities of your new instrument. Also, a training includes a troubleshooting session which will help you understand at first sight a potential problem or, more frequently, immediately understand this “problem” is really minor and can be solved in two clicks.

Training can be delivered “à la carte” from a purely operational training for production operators up to advanced sessions for R&D Senior Engineers.

Installation Qualification (IQ) – Operational Qualification (OQ)

Full IQ/OQ programs are available when a new instrument is installed at your plant. This program usually takes two days and include: the unpacking and the commented installation of the instrument, the review of all the documents and accessories supplied, verification of the calibration of the instrument, detailed training (Theory, troubleshooting, hands-on, Q&A), personalized support to your team for the first measurements.

In case of installation of complex or customized systems, this IQ/OQ will follow an acceptance protocol pre-defined by Lambda-X and its customer.