CLE-MENTOR® software

CLE-MENTOR® is the associated software with NIMOevo® to measure the optical performance of contact lenses. It offers the most advanced solution in terms of data integrity and integration in your production management system.

The core of the CLE-MENTOR® is its database which ensures a very high level of data integrity by prohibiting any modification of the measurement results. The advanced user management capabilities along with the availability of a full audit log, warranties complete traceability of your data.

These essential assets linked to many functionalities such as the lockable measurement templates or the automatic generation of reports (to name just a few) make the application directly compatible with the FDA 21 CFR part 11 guidelines.

CLE-MENTOR® is available for any existing NIMO-TR1504 and proposes 2 working modes: R&D mode and production mode.

R&D mode

This mode offers permanent direct access to an extensive set of options and measurement parameters from within the software. The R&D staff has full control and can easily modify any measurement parameter.

Available in R&D mode:

- Wavefront maps & Zernike coefficients

- Radial power maps & interactive power profiles analysis

- No lens conformity assessment is possible in R&D mode.

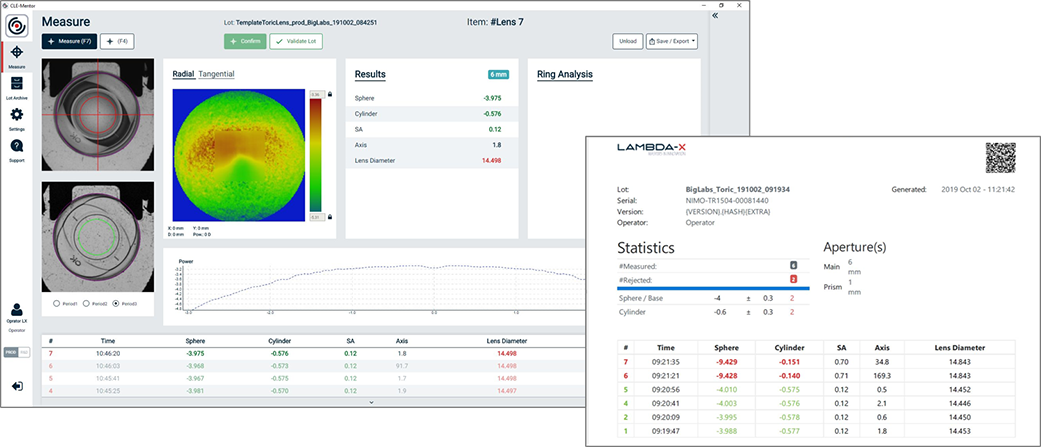

Production mode

A major effort has been made to make this mode as intuitive as possible and to guide the operator through natural steps. The lockable (but fully configurable) templates provide a safe environment prohibiting any modification of the measurement parameters even accidentally.

Workflows are available in production:

- One for specialty labs in which one measurement lot corresponds to strictly one lens and one report.

- One for volume production labs allowing lots containing a large number of lenses with the same characteristics.

- Define flexible batch measurement templates containing measurement options, conformity criteria, tolerance tables.

- Define automatic reporting preferences (PDF, CSV, images…).

- Measure large batches of lenses or unique lenses in a batch, keep full traceability of your measurements …

- Manage operators access rights through the user management interface.

- Operate your entire production with QR codes.

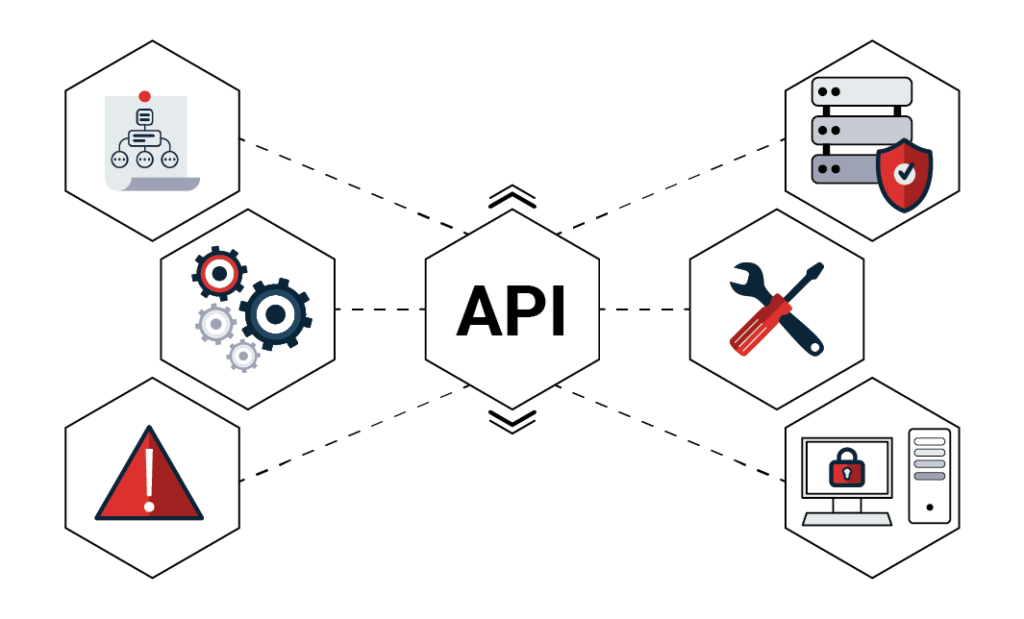

- Communicate with your central database and integrate NIMO in your automation line with the optional remote API.

- And much more

CLE-MENTOR® is integrated with FocalPoints and available for immediate deployment on your production floor.

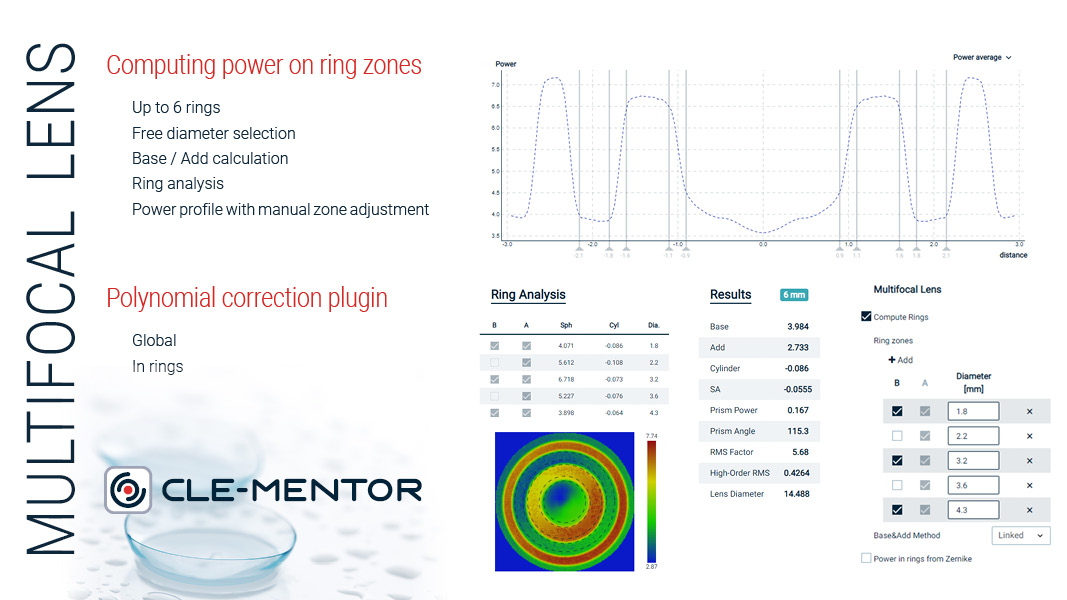

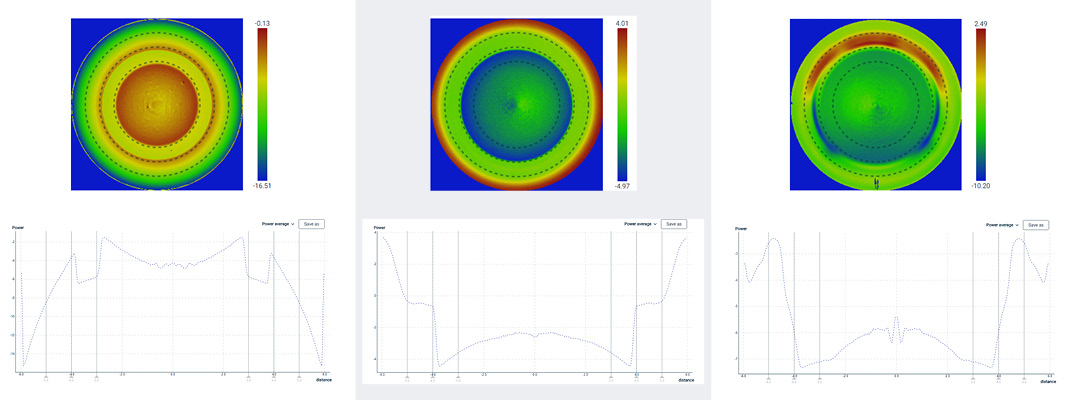

Multifocal Lens measurement

The Multifocal Lens measurement feature provides detailed representation of the power profile for fine adjustments of the ring borders, and results are presented independently for each ring, as well as a relation of selected base and addition.

This advanced functionality ensures that you have the most accurate measurements for your quality control processes.

This state-of-the-art software is the perfect solution for measuring complex contact lens designs with unique precision and ease, allowing you to select up to 6 rings (zones), adjust the diameter, and position the lens for optimal measurement accuracy.

In addition, EVO’s most precise wavefront sensor allows you to visualize the measurement in a selection of power maps, providing you with a detailed understanding of the power distribution across the lens.

This is just one of many impressive features of NIMO EVO and CLE-Mentor software, making it the perfect tool for the measurement and evaluation of modern contact lenses.

You need something more or different?

The API (Application Programming Interface) available as an option to CLE-MENTOR® makes the application extremely versatile, fully customizable and ready for production environments ranging from fully manual specialty labs operation to highly automated moulding plants.

Other custom solutions are also available:

- The design of the software is flexible and can be adapted for your various needs (results adapted, reports customized, etc).

- Our team of software engineers is available to develop custom features, workflows tr algorithmic improvements specific to the needs of your lens or production process.

- API based on WebSockets (and Python wrapper) giving you access to the full measurement data. It also enables the integration with virtually any in-house existing software system.

Easy to use example code is provided.