About Lambda-X Ophthalmics

Lambda-X Ophthalmics is a division of Verhaert Masters in Innovation, specialized in Quality Control for ophthalmic products with NIMO instruments.

Values

In line with its performance objectives and its willingness to ensure sustainable growth, Lambda-X has developed a quality management system compliant with the ISO 9001:2015 standard. Through this approach, Lambda-X implemented the necessary means to achieve the following objectives.

Continuously listen to stakeholders’ expectations and ensure that they are understood.

Encourage all staff to work on a daily basis to improve the company’s processes.

Identify and control all risks in order to ensure the ‘on quality’ and ‘on time’ deliveries of products and services.

Ensure full compliance with applicable laws and regulations as well as any specific requirements applicable to its activities.

Guarantee a full control of each stage of its research, development and production processes.

Ensure wellbeing of the collaborators through its approach to risk prevention vis-à-vis Safety and the Environment.

Ensure a high level of customer satisfaction and product quality.

Ensure optimal functioning of each department so that they effectively contribute to support the research, development and production activities.

The desire to understand and share knowledge is the cornerstone of society. The improvement and growth of the team’s skills is a matter of course.

History

Active since 1996 and recognized as a key player in the space sector, Lambda-X has developed and manufactured more than 30 instruments that have been deployed in space.

Lambda-X has gained its strong technological and managerial know-how by participating, as a project group member or as project leader, in various challenging space and aerospace research programs.

This expertise has allowed the company to expand its activities into a wide selection of industries where Lambda-X provides high-level optical engineering services based on a broad range of optical technologies.

By working in close cooperation with its customers, and thanks to its expertise in optics, mechanics, electronics and software, Lambda-X is able to provide the most suitable solutions to many complex industrial metrology challenges. Lambda-X’s constant concern is to deliver its customers maximized cost/performance ratios as well as fast and reliable after-sales service.

Lambda-X’s activities cover the conception of solutions tailored to customers’ specifications as well as the improvement of existing systems. The services proposed are ranging from concept development up to the serial production of certified/qualified products.

Additionally, Lambda-X has developed a proprietary range of instruments capable of quantifying the optical properties of ophthalmic corrective elements (such as spectacles, contact and intraocular lenses), as well as reflective surfaces such as mirrors. Those robust and fast instruments are typically used for quality control in both R&D and production environments.

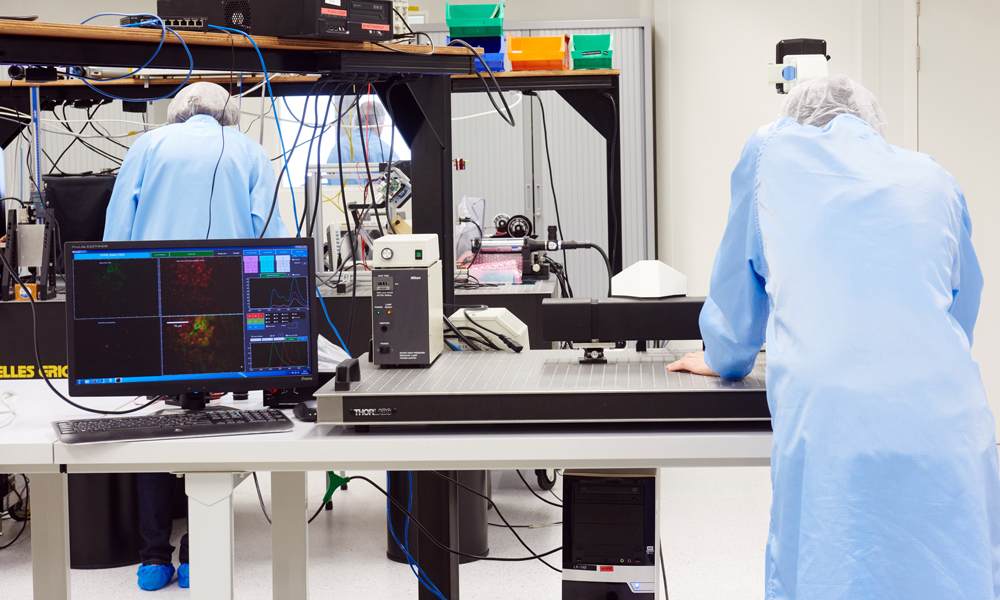

Finally, in a constant strive to improve the quality of its services and products, mid-2017 we decided to expand our premises up to 3.000 square meters hosting commercial administrative and technical team offices and more than 650 square meters of ISO 7 and locally ISO 5 clean room and integration areas.

Lambda-X designs, develops and manufactures optical and metrology systems as well as subsystems for space, defense, medical and industry.

Competences

Photonic toolbox

Enlightening your issue

- Light sources

- Illumination, light guides

- Detectors, cameras

- Optical systems, aspheres, freeform optics, reflective, refractive, micro-optics

Optical engineering

Conceiving your system

- Optical design

- Opto-mechanical & mechanical design

- Electronic design

- Ergonomic consideration

- Data handling

- Experimental demonstration

- Breadboards

Signal processing

Harnessing your information

- Algorithm

- Software development

- Image processing

Optical system validation

Working in your environment

- Ergonomic consideration

- Prototyping

- Environmental constraints

- Vibration & shocks, thermal, EMC …

Optical system manufacturing

Making series of your system

- Serial production

- Quality control

- Certification, qualification

- Contract manufacturing

Facility 3000 m² split in:

m² Offices

m² cleanrooms

m² stock & archives

Lambda-X Team

- We are a team of 43 employees

- Composed with highly specialized individuals in physics, engineering, software design, production and quality control